Testing, research and innovation

The time of producing, using and consequently throwing products away or even burning them, is over. By conducting tests and research on a pilot scale how plastics from household waste move through the sorting and washing process, we help our clients to increase the recyclability and eventually innovate towards 100% recyclable plastics.

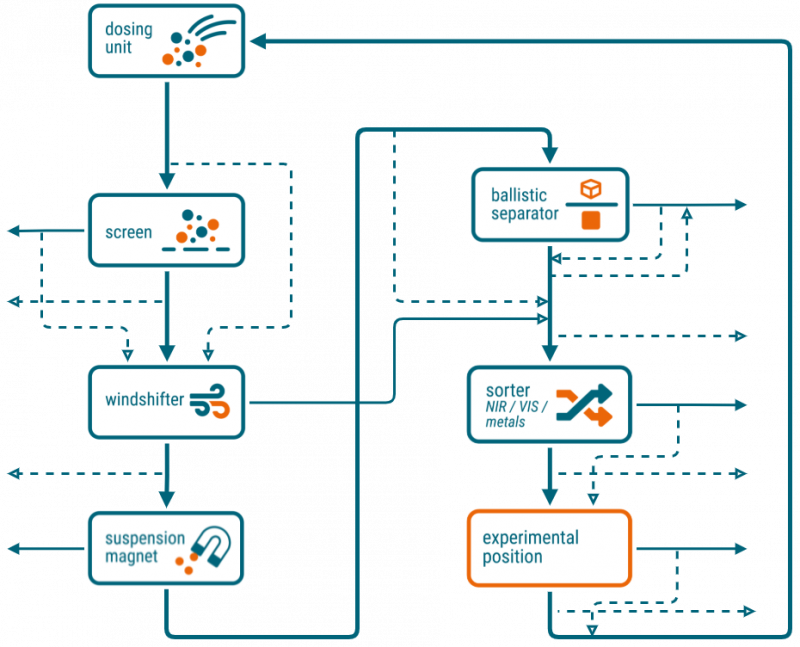

Our sorting line can simulate the complete sorting process (with a capacity up to 2000 kg per hour). However, it also has a modular set-up. This entails that every step in the sorting process can be run and sampled individually. In addition to the existing set-up, there is an experimental position to test new technology and equipment.

Currently, the NTCP is able to shred, wash in cold and hot water, and dry material for sample preparation for up to 1-100 kg. The industrial-size washing line, which investigates the washing process of plastics step-by-step in the same innovative way as the sorting line is being realised at the moment.

Questions from the plastic production- and recycle chain

With the results from our tests and experiments we are able to answer questions concerning the recycling of plastics from the entire chain.

We prefer to join in during the first steps of the design process of new plastic packaging. Because, as a result of working in a controlled environment, we are able to test new types of packaging in the design phase already. Then, together with our clients, we figure out what is possible and what needs to be done, in order to develop a kind of packaging that is highly recyclable.

At the same time, we are open to challenges and cases such as:

- How can our plastic packaging be sorted better?

- Why does our plastic packaging not end up in the right sorting stream?

- Can we apply new sorting technologies and processes and what is the effect on the downstream processes?

- How can we improve the purity and quantity of sorted streams?

- How can we prevent process losses of potentially valuable resources?

- Can plastic packaging be sorted more efficiently to enhance the recyclability?

- Where do interventions have the highest impact on the efficiency of the full recycling chain?

- Is the releasability of the label on our packaging sufficient during a cold water washing process?

- How can we optimise the washing process of the material stream we receive for recycling?

- How does my newly developed washing technique work at a washing process with a specific temperature/material?

Find answers with the NTCP

By executing practical tests and conducting experiments with our own sorting line, we collect quantitative data in a controlled environment about sorting in relation to material streams, process steps and process settings.

We store this data and knowledge in our knowledge database, which will be publicly accessible shortly. As such, we tackle the plastics recycling chain together based on data, which will help us to realise our joint circular ambitions throughout the complete plastics chain.

Artificial Intelligence (AI) in Recycling

We are also using Artificial Intelligence at our perfect sorting platform. AI is a state-of-the-art approach to deal with large dataset. The most important idea behind the perfect sorting platform is that you need a large number of characteristics of plastic objects to improve the sorting process. We look at the same objects with different sensors. Then we use AI to combine the sensor data into a useful classification.

Lees verderPackaging Sortability Evaluation

With this test we can determine the sortability of packaging materials using an industrial realistic protocol. The test includes a simulation of the consumer usage, collection and transport, a sorting evaluation, and a detailed optical sorter analysis. While the optical sorter analysis provides an overview of the detectability and classification with an industrial optical sorter, the sorting test provides insights into the actual sortability of the packaging through the whole process.

Composition Analysis

The objective of this research is to determine the composition of the chosen stream by using the NTCP’s characterisation protocol. We can test the behaviour of the sorted streams in terms of yield, impact, and possible interfering materials. With the information from the analysis, possible adjustments or decisions regarding choice of sorting stream (e.g. additional sorting and/or pre-treatment) can be made as a step towards a good sorting stream for the specific application.

Washing Test

One of the washing tests we perform is focused on the releasability of adhesives in a cold water washing process. We can do this with the protocol of the NTCP, which is focused on PP and/ or PE packaging with plastic labels or with another washing protocol. The results of the experiments provide insights into how well the labels are released during the washing process at a recycler.

Artificial Intelligence (AI) in Recycling

We are also using Artificial Intelligence at our perfect sorting platform. AI is a state-of-the-art approach to deal with large dataset. The most important idea behind the perfect sorting platform is that you need a large number of characteristics of plastic objects to improve the sorting process. We look at the same objects with different sensors. Then we use AI to combine the sensor data into a useful classification.

Lees verderPackaging Sortability Evaluation

With this test we can determine the sortability of packaging materials using an industrial realistic protocol. The test includes a simulation of the consumer usage, collection and transport, a sorting evaluation, and a detailed optical sorter analysis. While the optical sorter analysis provides an overview of the detectability and classification with an industrial optical sorter, the sorting test provides insights into the actual sortability of the packaging through the whole process.

Composition Analysis

The objective of this research is to determine the composition of the chosen stream by using the NTCP’s characterisation protocol. We can test the behaviour of the sorted streams in terms of yield, impact, and possible interfering materials. With the information from the analysis, possible adjustments or decisions regarding choice of sorting stream (e.g. additional sorting and/or pre-treatment) can be made as a step towards a good sorting stream for the specific application.

Washing Test

One of the washing tests we perform is focused on the releasability of adhesives in a cold water washing process. We can do this with the protocol of the NTCP, which is focused on PP and/ or PE packaging with plastic labels or with another washing protocol. The results of the experiments provide insights into how well the labels are released during the washing process at a recycler.

Artificial Intelligence (AI) in Recycling

We are also using Artificial Intelligence at our perfect sorting platform. AI is a state-of-the-art approach to deal with large dataset. The most important idea behind the perfect sorting platform is that you need a large number of characteristics of plastic objects to improve the sorting process. We look at the same objects with different sensors. Then we use AI to combine the sensor data into a useful classification.

Lees verderPackaging Sortability Evaluation

With this test we can determine the sortability of packaging materials using an industrial realistic protocol. The test includes a simulation of the consumer usage, collection and transport, a sorting evaluation, and a detailed optical sorter analysis. While the optical sorter analysis provides an overview of the detectability and classification with an industrial optical sorter, the sorting test provides insights into the actual sortability of the packaging through the whole process.

Composition Analysis

The objective of this research is to determine the composition of the chosen stream by using the NTCP’s characterisation protocol. We can test the behaviour of the sorted streams in terms of yield, impact, and possible interfering materials. With the information from the analysis, possible adjustments or decisions regarding choice of sorting stream (e.g. additional sorting and/or pre-treatment) can be made as a step towards a good sorting stream for the specific application.

Washing Test

One of the washing tests we perform is focused on the releasability of adhesives in a cold water washing process. We can do this with the protocol of the NTCP, which is focused on PP and/ or PE packaging with plastic labels or with another washing protocol. The results of the experiments provide insights into how well the labels are released during the washing process at a recycler.

Interested? Please contact us.

We will gladly tell you more!