Testing, research and innovation

In our opinion, the time of producing, using and consequently throwing products away or even burning them, is over. By testing and investigating on a pilot scale how plastics from household waste move through the sorting and washing process, we help our principals to increase the recyclability of their plastics and eventually innovate towards 100% recyclable plastics.

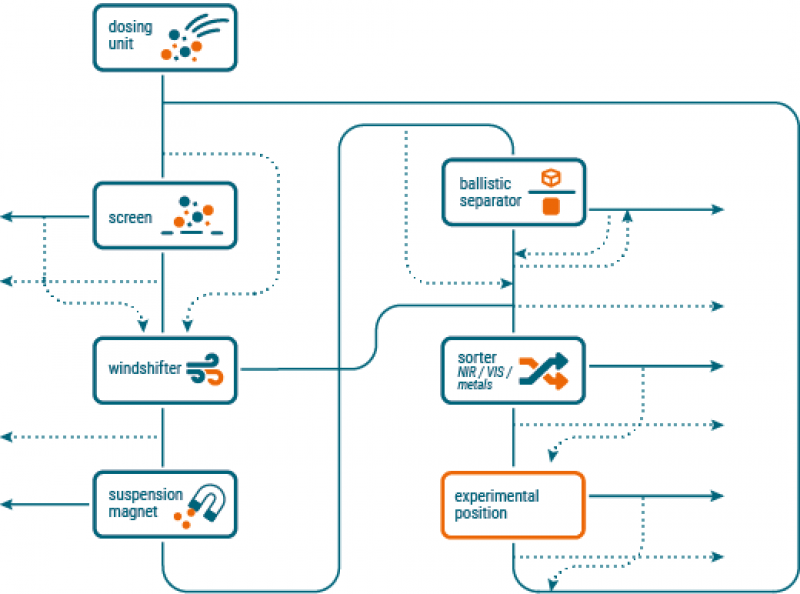

Our sorting line is able to handle the complete sorting process (up to 2000 kg per hour). However, it also has a modular set-up. This entails that every step in the sorting process can be run and sampled individually. In addition to the existing set-up, there is an experimental position to test new technology and equipment.

The washing line, which investigates the washing process of plastics step-by-step in the same innovative way as the sorting line, will be realised and implemented on a pilot scale at the end of 2020. As of now, the NTCP is able to shred, wash in cold and hot water and dry small samples for sample preparation.

Questions from the plastic production- and recycle chain

By the means of the results from our tests and experiments we are able to answer any question concerning the recycling of plastics from the entire chain.

We prefer to join in during the first steps of the design process of plastic packaging. Because, as a result of working in a controlled environment, we are able to test new types of packaging in the design phase already. Then, together with a principal, we figure out what is possible and what needs to be done, in order to develop a kind of packaging that is highly recyclable.

At the same time, we are open to challenges and cases such as:

- How can our plastic packaging be sorted better?

- Why does my plastic packaging not end up in the right sorting stream?

- Can we apply new sorting technologies and processes and what is the effect on the downstream processes?

- How can we improve the purity and quantity of sorted streams?

- How can we prevent process losses of potentially valuable resources?

- Can plastic packaging be sorted more efficiently to enhance the recyclability?

- Where do interventions have the hights impact on the efficiency of the full recycling chain?

Find answers with the NTCP

By executing practical tests and conducting experiments with our own sorting line, we collect quantitative data in a controlled environment about sorting in relation to material streams, process steps and process settings.

We store this data and knowledge in our knowledge database, which will be publicly accessible shortly. As such, we tackle the plastics recycling chain together based on data instead of a gut feeling, which will help us to realise our joint circular ambitions throughout the complete plastics chain.

Perfect Sorting enters next phase

After assessing over 300 SKUs from the brand owners in Perfect Sorting, the project just entered a new phase: the realisation of a demonstrator on AI-based packaging waste classification and sorting at the facilities of NTCP and later in the year at a waste management company. Perfect Sorting has partnered up with PolyPerception, specialised in waste stream characterisation using AI, to realise a classification and decision model to enable AI based sorting.

Lees verderControlled sorting tests using real waste streams

We perform tests and research on the behaviour of plastic packaging in the sorting process, e.g. to understand the efficiency of sorting specific packaging under realistic sorting conditions, to improve the recyclability of the product (towards design for recycling), or to test whether the packaging ends up in the right sorting stream. From the results of these tests we provide an advice which will help you to increase the recyclability of your packaging and/or link to design for recycling.

Process optimisation

We conduct tests and experiments in order to realise improvements in the sorting process or optimise interactions between sorting techniques with our sorting installation. For instance, to test and optimise process parameters of individual or integrated equipment. We work demand-driven: based on challenges from stakeholders in the value chain, without compromising our independency.

Facilitation of technology development

There are new innovations every day within the world of sorting and recycling plastics that increase their possibility of being recycled. Our sorting line offers the possibilities to physically integrate newly developed equipment or technologies and to test with real waste streams in an environment that is realistically scalable to represent the sorting industry. The results we obtain in our facility can be easily translated to an industrial scale.

Structured data collection and analysis

The NTCP knowledge database contains the data concerning process settings and test results. Using this data, we are able to conduct analyses between different studies in order to ensure that we, and our clients, don’t need to "reinvent the plastics wheel" over and over again. This database will be publicly accessible shortly, so stay tuned!

Characterisation of sorting streams

We determine the materials in the different streams during our tests at the facility and combine this with their chemical, physical and/or mechanical properties. We store this data and enhance our database, thereby supporting potential application opportunities of these streams in the future.

Perfect Sorting enters next phase

After assessing over 300 SKUs from the brand owners in Perfect Sorting, the project just entered a new phase: the realisation of a demonstrator on AI-based packaging waste classification and sorting at the facilities of NTCP and later in the year at a waste management company. Perfect Sorting has partnered up with PolyPerception, specialised in waste stream characterisation using AI, to realise a classification and decision model to enable AI based sorting.

Lees verderControlled sorting tests using real waste streams

We perform tests and research on the behaviour of plastic packaging in the sorting process, e.g. to understand the efficiency of sorting specific packaging under realistic sorting conditions, to improve the recyclability of the product (towards design for recycling), or to test whether the packaging ends up in the right sorting stream. From the results of these tests we provide an advice which will help you to increase the recyclability of your packaging and/or link to design for recycling.

Process optimisation

We conduct tests and experiments in order to realise improvements in the sorting process or optimise interactions between sorting techniques with our sorting installation. For instance, to test and optimise process parameters of individual or integrated equipment. We work demand-driven: based on challenges from stakeholders in the value chain, without compromising our independency.

Facilitation of technology development

There are new innovations every day within the world of sorting and recycling plastics that increase their possibility of being recycled. Our sorting line offers the possibilities to physically integrate newly developed equipment or technologies and to test with real waste streams in an environment that is realistically scalable to represent the sorting industry. The results we obtain in our facility can be easily translated to an industrial scale.

Structured data collection and analysis

The NTCP knowledge database contains the data concerning process settings and test results. Using this data, we are able to conduct analyses between different studies in order to ensure that we, and our clients, don’t need to "reinvent the plastics wheel" over and over again. This database will be publicly accessible shortly, so stay tuned!

Characterisation of sorting streams

We determine the materials in the different streams during our tests at the facility and combine this with their chemical, physical and/or mechanical properties. We store this data and enhance our database, thereby supporting potential application opportunities of these streams in the future.

Perfect Sorting enters next phase

After assessing over 300 SKUs from the brand owners in Perfect Sorting, the project just entered a new phase: the realisation of a demonstrator on AI-based packaging waste classification and sorting at the facilities of NTCP and later in the year at a waste management company. Perfect Sorting has partnered up with PolyPerception, specialised in waste stream characterisation using AI, to realise a classification and decision model to enable AI based sorting.

Lees verderControlled sorting tests using real waste streams

We perform tests and research on the behaviour of plastic packaging in the sorting process, e.g. to understand the efficiency of sorting specific packaging under realistic sorting conditions, to improve the recyclability of the product (towards design for recycling), or to test whether the packaging ends up in the right sorting stream. From the results of these tests we provide an advice which will help you to increase the recyclability of your packaging and/or link to design for recycling.

Process optimisation

We conduct tests and experiments in order to realise improvements in the sorting process or optimise interactions between sorting techniques with our sorting installation. For instance, to test and optimise process parameters of individual or integrated equipment. We work demand-driven: based on challenges from stakeholders in the value chain, without compromising our independency.

Facilitation of technology development

There are new innovations every day within the world of sorting and recycling plastics that increase their possibility of being recycled. Our sorting line offers the possibilities to physically integrate newly developed equipment or technologies and to test with real waste streams in an environment that is realistically scalable to represent the sorting industry. The results we obtain in our facility can be easily translated to an industrial scale.

Structured data collection and analysis

The NTCP knowledge database contains the data concerning process settings and test results. Using this data, we are able to conduct analyses between different studies in order to ensure that we, and our clients, don’t need to "reinvent the plastics wheel" over and over again. This database will be publicly accessible shortly, so stay tuned!

Characterisation of sorting streams

We determine the materials in the different streams during our tests at the facility and combine this with their chemical, physical and/or mechanical properties. We store this data and enhance our database, thereby supporting potential application opportunities of these streams in the future.

Our promise:

independent advice, supported with data on plastic waste streams, which you can (or should, really) implement immediately

Interested? Please contact us.

We gladly tell you more!